By recycling plastics, we actively contribute to mitigating the excessive waste produced by society, fostering a win-win scenario. Not only do we diminish the towering waste piles, but we also transform them into practical products integral to our daily lives. To enhance the efficacy of our efforts, we adhere to a structured process.

If you’re interested in joining forces with us, you can utilize the following steps to swiftly grasp the recycling procedure and participate in our recycling initiatives. Mastering these steps empowers you to establish your own recycling hub within your community, serving as a convenient drop-off point for plastics and enabling you to craft new products using our templates.

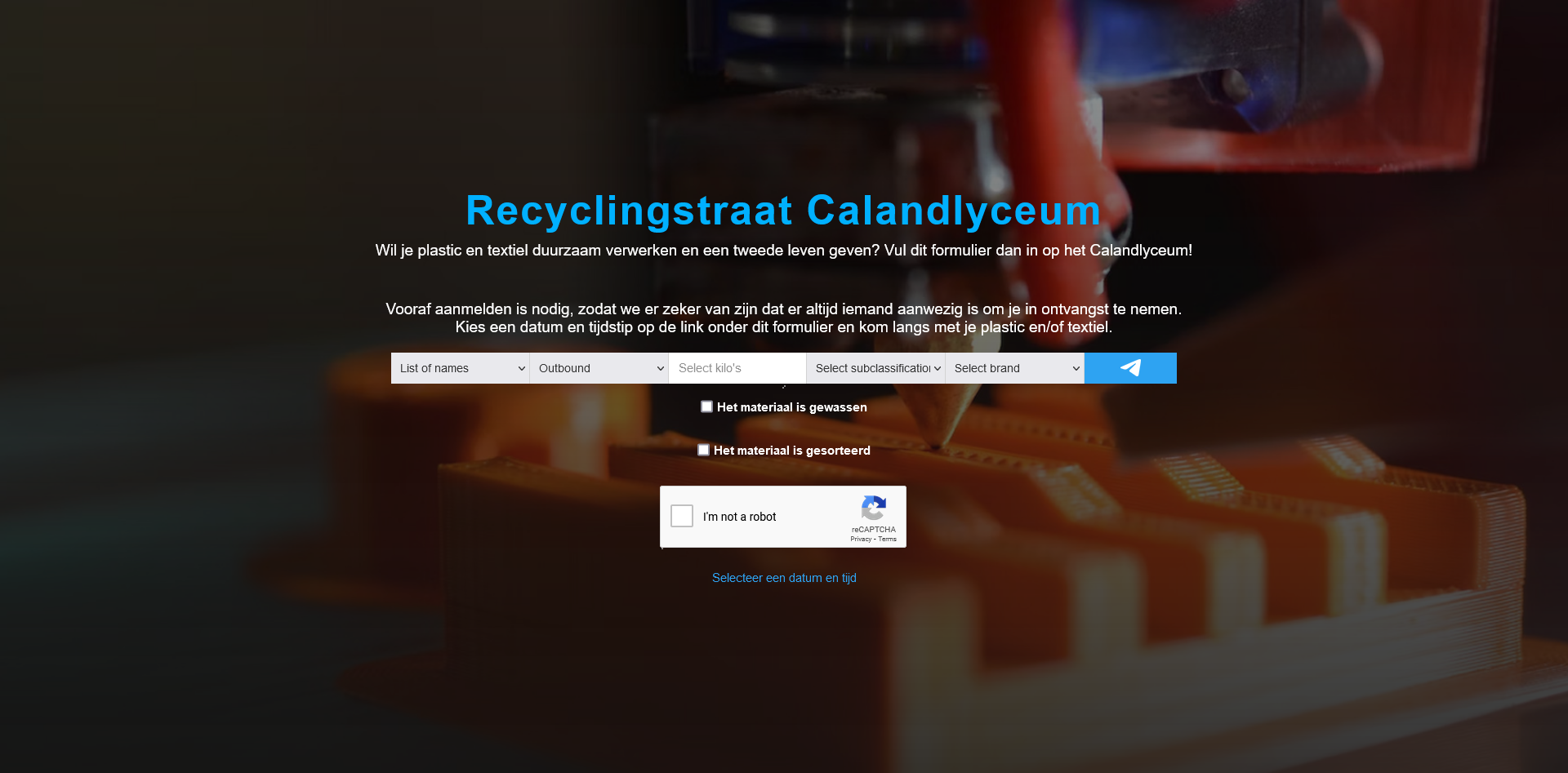

Registration process

In our recycling process, we are dedicated to harnessing the power of data to make well-informed decisions and constantly improve our operations. To achieve this goal, it is imperative to methodically document the volume and origins of the plastics we collect. You can choose to contribute anonymously or opt to register here for regular updates and valuable insights into our project. By registering, you’ll also receive reports detailing the amount of CO2 you’ve helped save through recycling.

Select a date

Choose your preferred time slot

We offer recycling bins at several locations for your convenience, where you can deposit your plastic waste. On designated days, we collect the plastics and host workshops to guide you through the entire recycling journey: from collection and cleaning to the creation of new products. Our workshops are complimentary, and participants receive a new product as a token of appreciation. Register now and choose one of the scheduled days to join us.

Sort and register

Register the different types of plastics

Once we’ve sorted all the plastics during the workshop, our next step is to record them in our system with our registration system. This data serves multiple purposes: we utilize it to generate statistics on plastic collection and inform future decisions. Particularly crucial is identifying the origins of these plastics, as this information enables us to present compelling statistics to the companies responsible for their production.

Recycling process

In our recycling process, we adhere to a series of steps to transform recycled materials into new products. Prior to a workshop, you also have the option to submit your own ideas for creations you’d like us to consider. While not all ideas may be feasible, we’re committed to collaborating with you to explore alternative solutions if your initial concept isn’t entirely achievable.

Deposit bins

Sort the content of the deposit bins

Upon receiving the deposit bins, our first step is to empty their contents and sort the plastics according to their respective codes. While there are 7 plastic codes, our primary focus lies on 1 (PETE), 2 (HDPE), and 5 (PP). Plastics with other codes will not undergo further processing; instead, they will be disposed of, albeit after being shredded to reduce their size for easier disposal.

Shredding process

Clean, cut, and shred plastic

We find great satisfaction in our meticulous process of transforming large plastic chunks into smaller, more manageable pieces. Beginning with sizable volumes, we carefully wash and cut the plastics before commencing the shredding phase. Not only does this method efficiently utilize space, but it also yields a valuable end product that plays a significant role in the recycling journey. It’s a rewarding process that combines environmental responsibility with practical usefulness.

Sort granulate in boxes

Further process or distribute the granules

Once the plastic is sorted, washed, and shredded, it will be stored in separate boxes, categorized by color. These boxes will be housed in our storage facilities or will be dispatched to various partners for further processing at different locations. During workshops, we will handle different batches of plastic at the designated location.

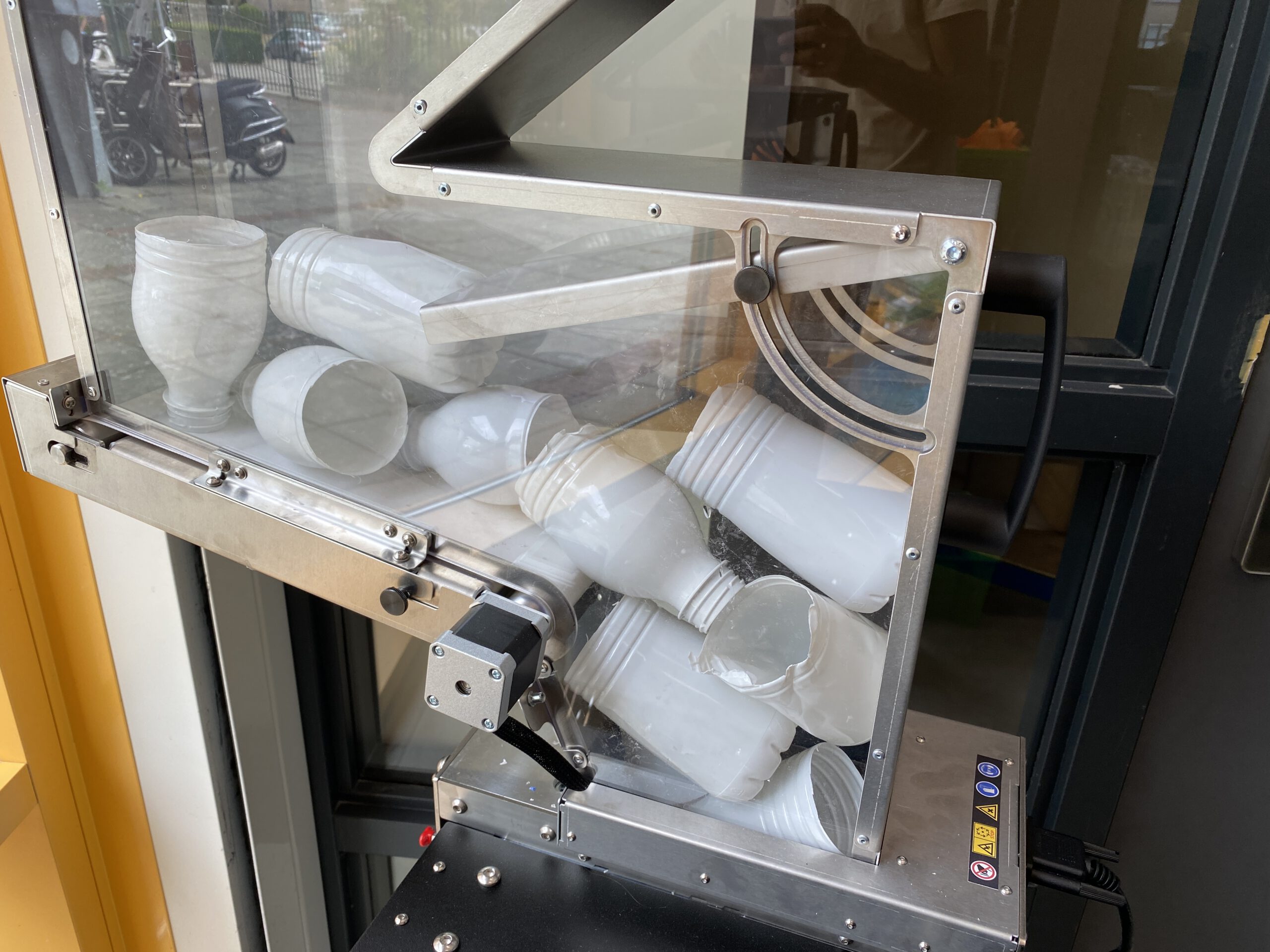

Injection process

To create products in all shapes and sizes

We boast a diverse array of molds, and our in-house capability allows us to craft even more variations swiftly. With the ability to create molds on-site, we ensure a vast range of options for product manufacturing. Our process is remarkably efficient; within minutes, we can produce products by injecting materials into the molds. One of the greatest advantages lies in our ability to leverage the machine’s warmth to simultaneously produce multiple items, significantly reducing production time and increasing output.

Ready made products

To take home and/or for practical use

During our workshops, participants delight in crafting personalized items from leftover plastic, providing both an engaging experience and a sustainable solution. After the products have cooled in the mold, we carefully remove them and perform a final polish, preparing them for versatile use. While some molds are specifically designed for practical items, our products serve multiple purposes. If they ever become surplus to requirements, we seamlessly recycle them, thereby perpetuating a sustainable loop of production and reuse.

Our current projects

Recycling plastics

We convert waste plastic into valuable resources, crafting high-quality 3D printer filament and injection molding material for a wide array of products.

Recycling textiles

Building upon our success in plastic recycling, we are now shifting our focus to textile recycling. Our aim is to create recycled products and assist students in launching sustainable businesses.

© 2024 De Recyclingbank. All rights reserved